Just got a great reminder of why it's important to publish your work and promote the work of other makers. I've been slacking recently, not publishing or documenting much of anything.

I am cycling away from jewelry-making and back to Arduino type projects. Working with jewelry gives me immediate feedback from real living people through sales and human interaction. I get tiny jolts of ego juice when people buy my stuff, not a lot of sales mind you, but enough to keep me going.

With the Arduino and industrial design stuff however, I had started to feel both overly egotistical (talking about my stuff all the time) and unsure if anyone really cares about the projects anyway. These types of projects can seem tedious to many people (all my friends) and the time-scale is so much longer that few people wait around for the pay-off. Who really wants to hear the details of a five-week project that includes coding, electronics, 3d printing and industrial design?

Then someone did one tiny thing and it helped me - they published something similar to my work.

I love it when I see professional designers come up with solutions that are similar to mine. When people I admire solve the same problem and get the same result, it makes me feel like I did something well.

I'm not designing professionally these days, but it still feels good - like maybe I've still got it - even when the professional's design is much better than mine. That little ego-boost is always pleasant, but it really means something when you're designing in isolation.

A few years ago I made a

Musical Doodle Bug for an Instructable. It's a cute toy piano thingy with a gap-toothed face. You can play musical notes and arpeggios while LEDs light up to go along with the music. You can change the speed and octave just by rotating the object. You can change modes with buttons and switches. And I tried to make it kid friendly with a cute case made from common craft supplies. I wanted to make something with my favorite new Arduino board that included fun activities for all ages and skill levels.

Last week, I

found a project from Adafruit (

one of my favorite maker-centric companies) that used the same board that also played music with a cute, toothy face. Finding that project made me smile. Adafruit's version is much more refined and polished. But the basic approach is the same.

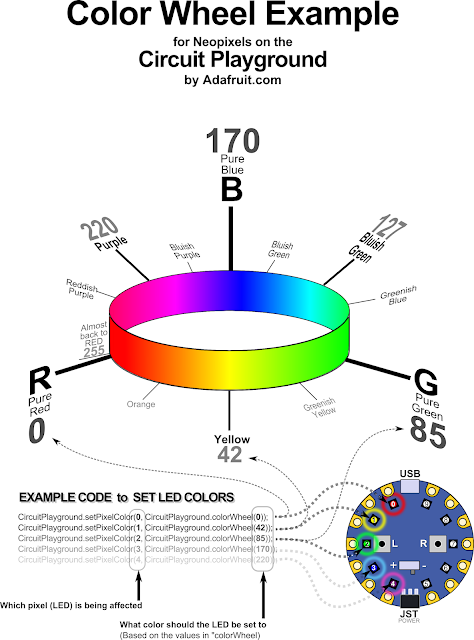

Even better, Adafruit is the maker and designer of the board used in the project. It's their

Circuit Playground board, an all-in-one Arduino style board that comes complete with a huge collection of sensors and outputs built right onto the board. I fell in love with this wonderful board as soon as I saw it. It's perfect for new programmers and it's cheap. But it's also powerful enough for advanced designers and programmers to use in "real" projects.

I don't get much feedback on my Arduino projects since I'm the only one locally who really uses Arduinos and such. I enjoyed making the project, but I wasn't sure if it was any good. So when I saw the creators of the board design a project for it - that used just a few of the same elements and approaches that I used - well it made my day, it made me happy, it gave me confirmation. Maybe I was on the right track after all.

This might seem silly and trivial. (

It's not the first or only "face piano" after all - no big deal.) If you work in a creative environment and are surrounded by skilled and talented designers all day, then you get constant feedback. You get confirmation and guidance from peers and end-users. Or, if you have a large local maker community you can reach out to them, talk to them in real life or even collaborate on projects.

But if you work in isolation, then it can be weeks or even months between comments from another person (typed and anonymous). It's difficult to know if you are on the right track, or know if any one else is even interested in the same things as you. I've annoyed dozens of local people promoting the joys and wonder of this type of making - to the point that their eyes glazed over. By this point I know I have to depend on the internet to provide feedback from like-minded designers and makers.

|

| Seriously, who in their right mind does flow-charts much less documents them and publishes them. Well I did, and it helped me understand what I was trying to accomplish. If you do too, then just know that you are not alone. |

So here's a big shout out and thank you to everyone who publishes their projects - big or small, simple or sophisticated, artistic or practical. You folks help keep me going. And I'm sure I'm not the only one. There are people on remote jobsites, in small communities, or who just have family responsibilities that keep them from being part of a physical IRL community. We tinker and make and keep ourselves halfway motivated with very little outside feedback.

But if one tiny echo of my project can make me this happy and motivate me again, well it makes me want to publish more projects just in case there is one other person who is working on a similar project and needs some support.

BTW, Adafruit does an excellent job of both publishing and promoting other makers' work. Their skill at creating and nurturing a community is amazing. Their attitude is one of the reasons I'm still involved with electronics and Arduinos when everyone around me thinks it's weird and boring. A big shout out to them as well. Go visit their forums and participate.

Just remember - you are not alone. There are other people, normal people without a million subscribers, who tinker and putz in the basement or garage. It's good to hear from them and from you. I learn from you just like the big names. I am impressed by your work and your creativity. Please publish more of your projects. Help keep me motivated and I promise I will publish more in return.